Newsletter december 2023

We wish you a merry Christmas and a healthy and happy New Year!

After a year of analysing and optimising buckled storage tanks, mixing en stirring, broken shafts, flaming flares, flow meters and earthquakes, we celebrate the end of the year with a fun simulation. Resulting this year in a CFD analysis of a smokeless fire pit, the improved version of fire basket and fire bowl. The CFD simulation in FloEFD is coupled to a FEA (finite element analysis) to calculate the stresses caused by the thermal expansion of the material (stainless steel).

CFD analyse smokeless fire pit

The smokeless fire pit

At the end of the year people like to kindle a fire, be it a candle or a fire pit. Traditional fire baskets and bowls can cause a lot of smoke. The smokeless fire pit should improve this. A key design point of the smokeless fire pit is the double outer wall and air supply to the file just below the upper edge. The double outer walls said to have a “chimney effect” that better guides the secondary air into the fire. But is that really the case? Does it indeed have a beneficial effect on smoke production?

We modelled a fire pit in Siemens Simcenter FLOEFD and performed the analysis. The logs of wood are stacked according to the “Swiss method”. Wood gas is flowing from all the outer planes of the logs. The wood gas mixture reacts with the oxygen from the air and is converted into CO2, water vapour and CO. Furthermore, of course, there is heat transfer by convection, radiation, including radiation from the flue gas, and heat conduction through the steel.

As in real life, you have to light the fire by reaching the minimum ignition temperature of the gas mixture. We do that here by giving a small volume an initial temperature above this temperature for a short time. Once the fire is lit and there is sufficient air and fuel supply then it continues to burn because the temperature remains high enough.

To measure the smoke development, we have to know how smoke originates. One of the causes is unburned fuel. If the combustion gases have unburned fuel and the temperature is below the ignition temperature, particulate matter and with that smoke will develop. We can measure this by creating an “isosurface” of the volume with fuel and plot the temperature locally. In places where the temperature is below the ignition temperature, smoke will develop.

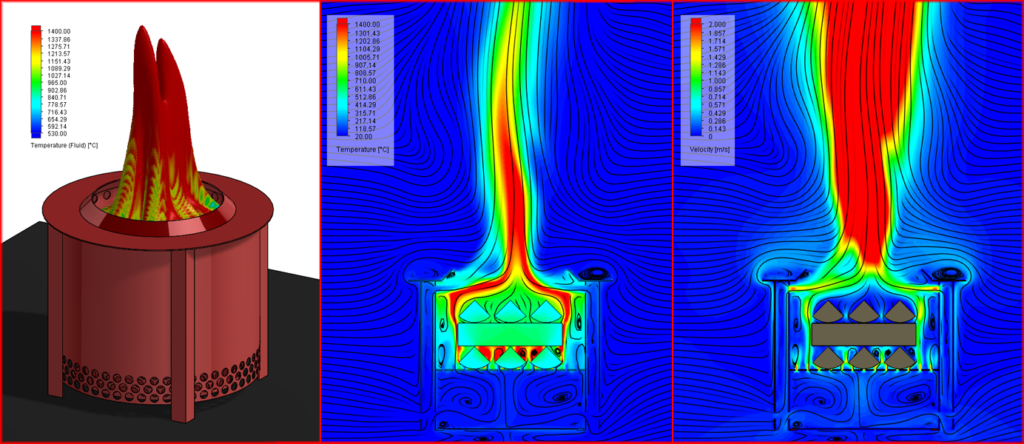

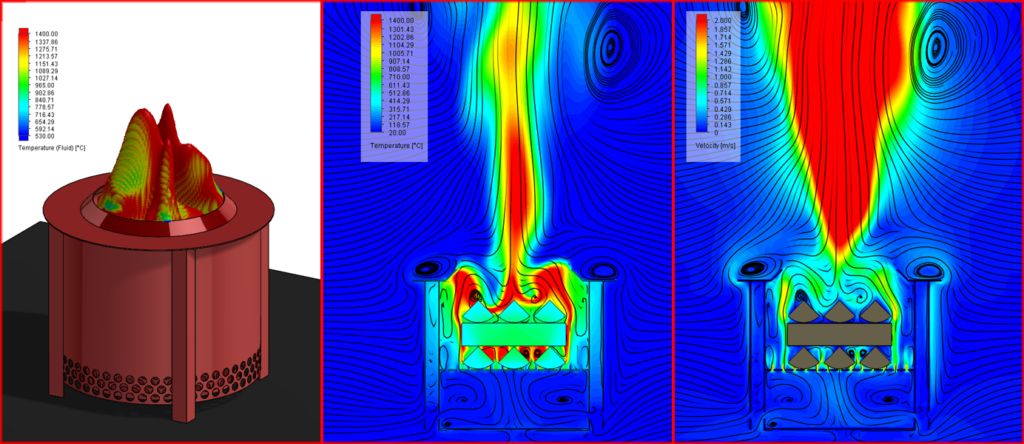

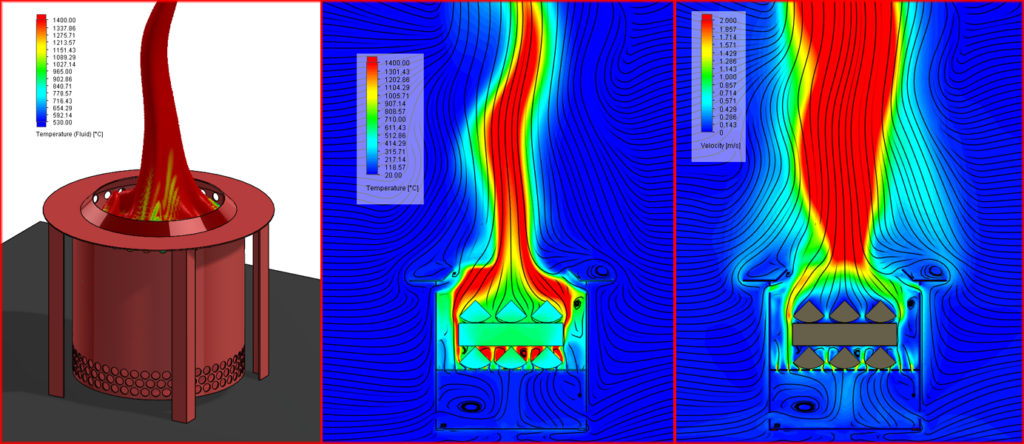

We have analysed three variants:

- Double wall with secondary air flow to the fire

CFD analyse smokeless fire pit

- Double wall without secondary air flow to the fire

CFD analyse smokeless fire pit zonder secundaire luchttoevoer

- Single wall with secondary air flow to the fire

CFD analyse smokeless fire pit zonder buitenwand

Results: both versions with the secondary air flow show the same results, which means that the air suction isn’t affected much by the “chimney effect” of the double wall. The airflow through the secondary air supply is mainly determined by the fire intake and not by a chimney effect in the double wall. The double wall does heat up the air, which is beneficial for combustion, and in this case the outer wall actually gets hot, about 200°

The version without a secondary air supply does seem to give a slightly higher risk of smoke; in the places where the flame burns close to the edge of the fire pit, the gas cools down locally very much so that there is a risk of it falling below ignition temperature.

With Finite Element Analysis FEA (also done with Siemens Simcenter FLOEFD) the structural Von Mises stresses caused by the thermal expansion of the material are calculated. These stresses are high and above the yield limit, which will cause permanent deformation.

HEC closed between Chrismas and New Year

We are closed from December 27th 2023 through January 1st 2024 . We hope to be of service again starting January 2nd.